What is Nano-Clear?

Nano-Clear® is an advanced protective clear coating that keeps your surfaces looking their best for over a decade.

It is resistant to fading, UV, weathering, chemicals, salt, solvents, and graffiti. Making it ideal for protecting a wide range of surfaces, such as aluminium joinery, machinery, infrastructure, playgrounds and more.

Incredibly hard and durable, lasting three times longer than standard paint. It is hydrophobic, making it easy to clean, and a cost-effective solution for keeping your surfaces looking great.

We can adjust the gloss level with Nano-Clear® to full-gloss, semi-gloss, or matt creating the perfect look for your needs.

Nano-Clear® is a sprayed-on application and we can treat your windows in-situ, minimizing disruption to your home or business. Some of our license owners have spray booths available for machinery and outdoor furniture treatments.

If you're looking for a protective coating that will keep your surfaces and assets looking their best for years to come, then Nano-Clear® is the perfect solution.

Nano-Clear® Property Overview

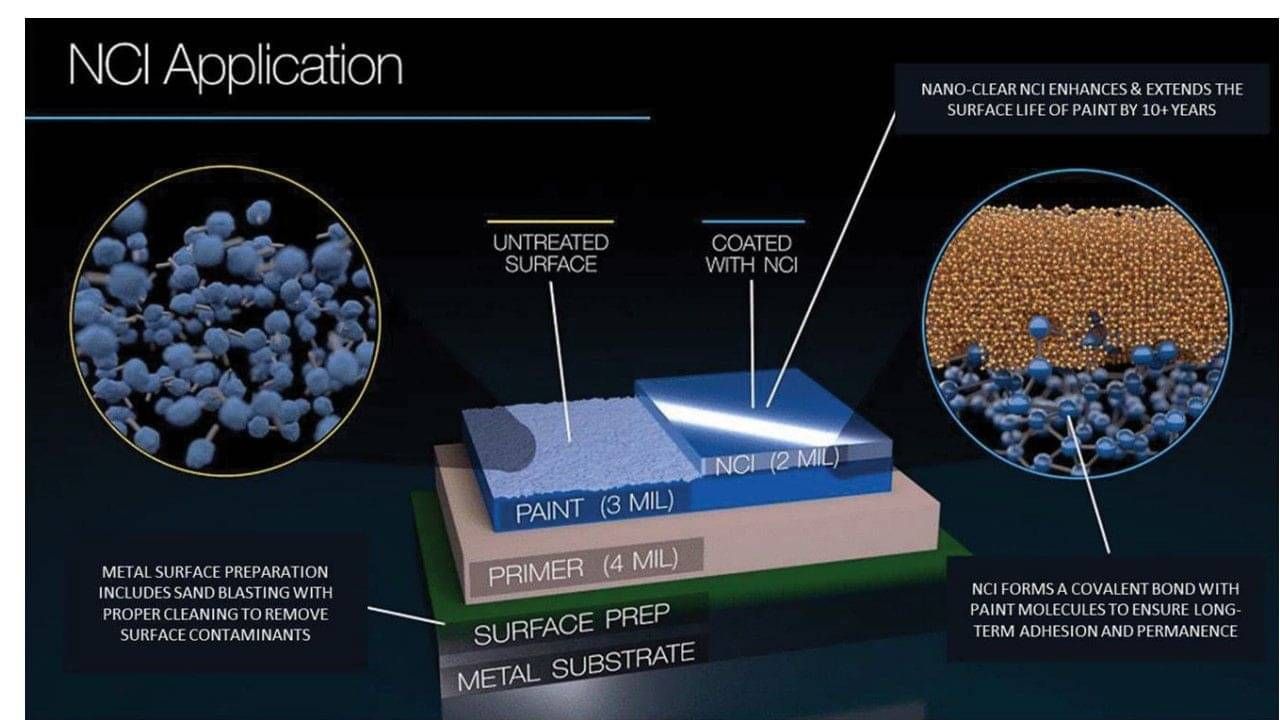

The automotive industry commonly applies high performance "clear topcoatings'" over painted surfaces to mitigate the negative effects of environmental exposure (acid rain, harsh UV rays, car washing, stone chips...). Automotive OEM clear coatings are well known to provide long-term surface protection against the environment when applied over painted surfaces. The industrial paint market currently relies on pigmented coatings alone without the use of a high performance clear coating. What is needed is a high performance clear coating designed to dramatically extend the surface life of industrial painted surfaces.

Nano-Clear® is designed to dramatically enhance and extend the surface life of 'newly-painted' or 'oxidised' painted surfaces by 10+ years. Organisations have invested billions of dollars to protect high-value assets from corrosion, scratching, chipping, chemical attack and weathering. Many of these assets were painted using inferior paint materials not designed to withstand long-term weathering and use. Organisations have various options when these painted assets degrade:

1. Do nothing and allow the paint weathering cycle to continue (resulting in decreased corrosion, chemical and UV resistance).

2. Replace the existing paint system using the same conventional systems (epoxy topcoat, polyurethane or latex).

3. Enhance and extend the surface life of 'new' or 'oxidised' painted assets by 10+ years using Nano-Clear.

Conventional industrial paint systems including epoxies provide good corrosion resistance and initial surface hardness, but unfortunately fall short in long-term UV resistance and weathering. Two-component polyurethanes provide good UV resistance and weathering, but typically cost much more than epoxy or polyester topcoats. Unfortunately, conventional paint systems like topcoats and epoxies begin the oxidization process or “chalking” from weathering within 6 months from application. This surface chalking phenomenon is actually degraded paint that resides on the surface from UV exposure and weathering.

Nano-Clear coatings penetrate deep into the smallest pores within newly painted or highly oxidised paint surfaces to form a highly cross-link dense/hard coat surface. Nano-Clear coatings provide dramatically longer surface protection over conventional automotive, marine, aerospace and industrial paints including epoxies and polyurethanes. How can we make this claim? Nano-Clear coatings provide dramatically higher crosslink density over conventional one-component and two-component coating systems. Nano-Clear coatings prevent UV degradation of the substrate by absorbing harmful UV rays.

What is crosslink density and why is it important in coatings? Crosslink density is defined as the concentration of chemical bonds within a polymer. Higher concentrations of chemical bonds within a polymer improve physical properties. Conversely, lower concentrations of chemical bonds within a polymer decrease physical properties. Increasing crosslink density increases material hardness, chemical resistance and long-term UV resistance.

How does crosslink density relate to a coatings longevity? High crosslink dense coatings provide increased molecular bonds. Increased molecular bonds are more difficult to break down by chemical attack, surface scratching and UV degradation from sunlight exposure. Highly crosslinked coatings provide increased physical performance and increased longevity as compared to lower crosslinked coating systems.

History of Nano-Clear®

Nano-Clear® started journey with Thomas Choate at 16 years old, working at a dental lab in Brighton, MI, USA.

By 1986, he was making life like dental prosthetics at Felix Dental Arts for local sports stars.

In 1989, Thomas founded Felix Dental Manufacturing, creating the world's first polyurethane hybrid dental polymer.

Later, he sold the company to ADS, which continues to sell Felix products to top dental experts and universities.

In 2003, Thomas founded Nanovere Technologies, focusing on developing a first-of-its-kind nano coating with unique properties like being very scratch, chemical, and UV resistant with self-cleaning abilities.

After extensive research, in 2008, Nanovere launched the world's first Dendritic Polyurethane Coating System, collaborating with giants like GM, Jaguar, and Boeing.

By 2009, collaborations extended to Bayer Material Sciences and others.

In 2011, Nanovere teamed up with Nippon Paint/CyGlaz, Asia's largest paint producers.

Nano-Clear was introduced to New Zealand in 2012

2013 saw the launch of the first ambient cure 'Nano-Clear Coating', setting new benchmarks for automotive and aerospace industries.

In 2019, Nano-Clear/Nanovere won at the Corrosion Innovation Awards for their contribution to corrosion control.

Nano-Clear, still made by Nanovere in Brighton, USA, is now sold worldwide through select distributors. It offers a range of scratch, chemical, and UV resistant nano-coatings, providing lasting clear coat protection for homes, vehicles, boats, and industrial assets.

Enquire Now

Nano-Clear® is proudly New Zealand owned and operated

Call: 0800 626 625 / 0800 NANOCLEAR

North Island 0276250521

South Island 0278830009